MSL Technology by Red Paddle Co

Strong points about Red Paddle Co:

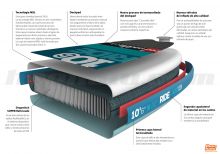

MSL: a lightweight material produced industrially with innovative components.

MSL (Monocoque Structural Laminate) is the new material technology by Red Paddle Co.This technology is made using a completely industrial process to eliminate human error. It uses lightweight materials and optimal manufacturing processes.

All of this means that your SUP board weighs 2kg less! The board is also stiffer in lower pressure water. MSL combined with TEC Air manufacturing processes allows them to achieve the best possible results.

TEC Air technology is a thorough process used by Red Paddle Co to optimise and offer excellent results during all SUP board production phases.

Every inflatable board built by Red Paddle Co has been produced using TEC Air specifications to ensure a high-quality product.

Under the motto of "La Fuerza viene por Adentro (strength comes from within)", Red Paddle Co puts emphasis on the use of high-quality materials. The membranes for the boards are made using the DropStitch technique which offers a high density per inch and greater resistence at higher pressures. These membranes don't follow a linear pattern like other manufacturers but make use of multi-threading which can be views as a stitch in the board itself. Membranes can achieve different thicknesses that will be in accordance with shapes and sizes of each Paddle Surf board with the aim to achieve greater volume and stiffness at a lower air pressure.

Their design exceeds any expectation and offers peace of mind and confidence for use on any surface. Red Paddle Co inflatable boards are constructed with two layers - a bit like two SUP boards in one. First, a board is created by laminatng the DropStitch membrane twice, this time with the help of high pressure rollers that help to shape the board, specifically its rocker (or lift tip).

But to be even quieter, once the second laminate process is complete, the edges are inforced with two additional layers to create a quad-edge construction, ensuring an almost bulletproof construction. Goodies laminates that are included in the edges get have added protection for the most delicate part of the board because it has DropsStitches all together and this part normally takes the most punches and could therefore have a puncture, air leakage or the board could completely deflatel, the good news is that with Red Paddle Co boards this will be almost impossible.

Once the laminates and reinforcement have been completed, EVA anti-slip pads can be attached to the keel fin.

Another feature of this technology is that it manages to withstand high atmospheric pressures than all other inflatable SUP boards on the market, allowing you to inflate the boards from 15psi to 25psi to make the board stiffer with a higher pressure.

The RSS system is unique and exclusive to Red Paddle Co.

By combining MSL and TEC Air technology with the RSS system, you can be assured of the best possible results.

The RSS consists of two semi-rigid battens which are inserted into two separate compartments located on the edges of the inflatable board. This ingenious system is exclusive to Red Paddle Co.

This is achieved thanks to a 40% increase in the rigidity of the boards.

RSS Battens are used in all the 100mm / 3.93" thick boards (excluding 9'4" Snapper), in order to give the same stiffness as the 120mm / 4.72" boards, maintaining the handling performance despite the thinner boards.

- Ultralight construction

- Totally industrial processes to eliminate human error

- RSS increase in rigidity of 40%

- High-quality materials

- High density of DropStitches per inch.

- Operate15Psi until 20PSi

- All boards are double-laminated

- Reinforced edges with two additional layers, creating a Quad Rail Construction